Repairing America Since 1966

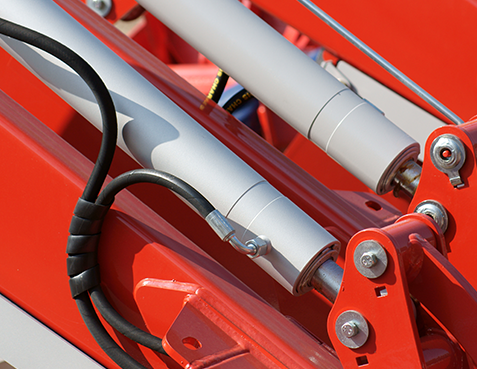

OUR HYDRAULIC CYLINDER SERVICES

Pickup and Deliver Cylinders

Whether your cylinder is at your shop or on the job site, we will pick up and deliver any size cylinder for a fast turnaround. For any out of state repair needs, Nationwide LTL Trucking is also available.

Complete Cylinder Inspection

All cylinder components are inspected, measured, and recorded on our detailed inspection sheet. By verifying the clearances on all seal and wear surfaces, we can eliminate potential problems and assure maximum seal life and cylinder performance.

High Torque Capabilities

Our heavy-duty torque bench has the capacity to remove piston nuts and glands up to 50,000 ft. lbs. During re-assembly nuts and glands are torqued to the proper specifications.

Precision Honing

All cylinders receive a light hone during our standard re-seal process. This allows a cylinder to perform at optimum levels and live longer without leaks. Our automatic honing machine can correct any irregularities or heavy scoring to renew barrel life.

Re-tubing

When cylinder barrels are not corrected through the honing process, new tubes are custom made using OEM specifications.

Automated Welding

Manufactured rods and barrels are auto-welded, creating the most consistent bond/weld possible.

Assembly Process

Cylinders are assembled using OEM quality parts. During pressure testing, cylinders are stroked multiple times. Cylinders are then pressurized to operating pressure on both sides of the piston to test against internal and external leakage.

Large Bore Capabilities

Remke’s Garage has unique experience in rebuilding large bore hydraulic cylinders. The ability to do work on a 24" bore tube or an 18.000" chrome rod takes heavy-duty large capacity machinery and experienced machinists. Technical skills are required to do final assembly on large cylinders.

Rod Re-finishing

Cylinder rods are checked for straightness during the inspection process. Rods that pass inspection are polished to eliminate minor imperfections and renew chrome finish.

Rod Replacement

On-site manufacturing using our inventory of metric and standard rod stock provides quick turnarounds. We believe in only using the highest quality 100,000 tensile strength or induction hardened chrome rod stock to maximize cylinder performance.

Muncie Dump Truck Cylinders

Remke’s Garage is a distributor of MUNCIE cylinders, specifically designed for dump trucks and dump truck trailers. Please note, we supply these cylinders but do not perform repairs or service on the vehicles themselves. Call today to learn more about our available selection.

-

Pin-Pin Cylinders

The pin-pin mount cylinder is engineered to reduce oil consumption and increase dumping speed. As one of the lightest cylinders available, the pin-pin cylinder is a great addition to dump trucks.

Pin-pin cylinders have increased rigidity due to tight machining tolerances. They feature solid stop contact faces and create a larger overlap between stages. These improvements help prevent accidents due to vehicle roll-over, increasing dumping safety.

-

Trunnion Mount Cylinders

The trunnion mount cylinders increase dump body capacity by reducing or eliminating the dog house. They are low maintenance with tight machining tolerances for increased rigidity. Trunnion mount cylinders also have solid stop contact faces* and larger overlap between stages.

MUNCIE cylinders are one of the most stable and strongest cylinders on the market.

1 Year/ 2400 Hour Warranty

We stand behind our work and all cylinders rebuilt are serial numbered and recorded in-service history.

Request Appt.

Repairing America Since 1966

OUR SERVICES

Repairing America Since 1966

REQUEST APPOINTMENT

Repairing America Since 1966

LOCATION

Our State of the Art Facility is located just 1 mile west of Union Rd. on

Illinois Route 20 in Marengo, IL.

8122 S. GRANT HWY. | MARENGO, IL 60152